VSR 400

THE MODEL

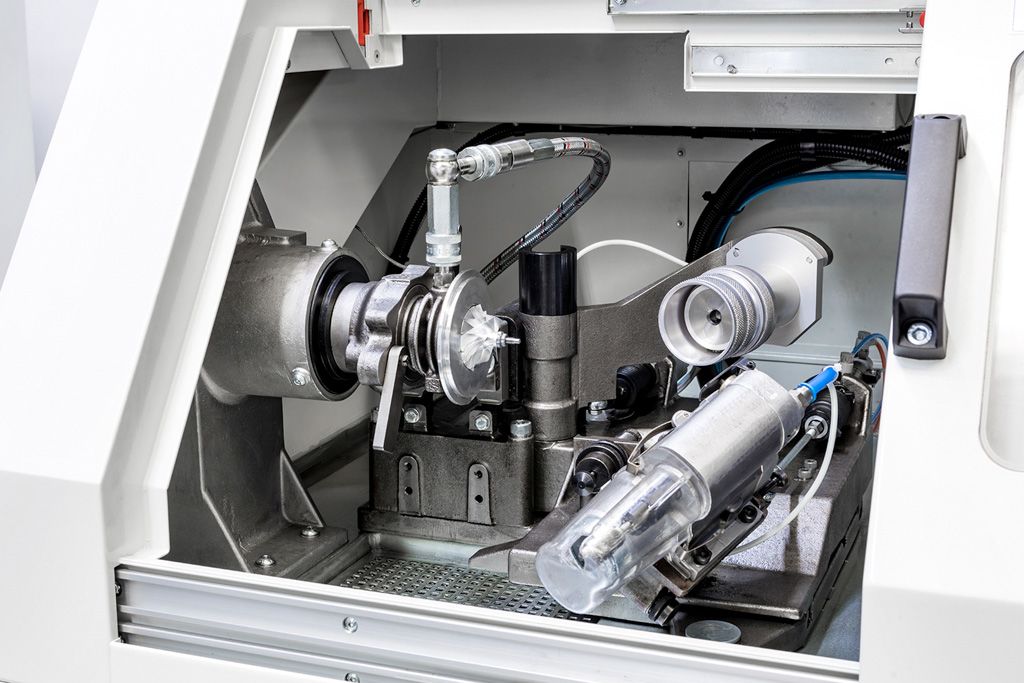

The VSR 400 Series is a Vibration Classification Platform (VSR ™) designed for the OEM’s highest volume, lowest volume aftermarket customer and is available with a number of features to cater to high volume turbo production. The VSR 400 is suitable for light / medium commercial vehicle (CHRA) turbocharger cores.

Following the success of the VSR MK3 in 1999, customers demanded a machine capable of continuous operation. Turbo Technics responded to this demand with the introduction of the VSR 400 range in 2004.

ACCESSORIES

OPTIONAL

TURBINE ADAPTERS

A wide range of CHRA-specific quick-change housing adapters are available, including standard and reverse rotation types.

ACCESSORIES

Turbo Technics offers a wide range of accessories and adapters for all test machines. Additional optional components allow machines to be tailored to customer specifications.

UK DESIGN AND CONSTRUCTION

LATEST TECHNOLOGY

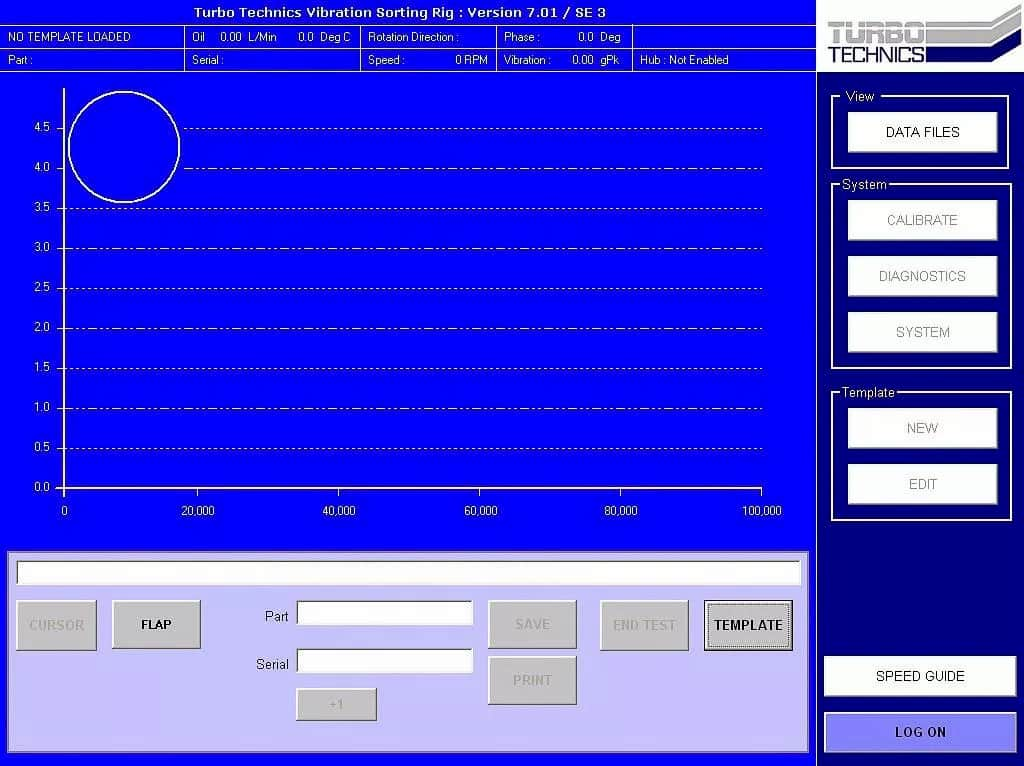

As with all TT machines, the VSR 400 uses the latest touch screen technology, an intuitive interface, and built-in connectivity that enables remote TT technical support over the Internet. Easy-to-use software can be quickly mastered in a few hours with additional free training available at TT UK HQ if needed.

All Turbo Technics machines are designed and built in the UK and available through the TT dealer network.

VSR 400 SERIES

COMPARE MODELS

Machine type

VSR 400

VSR 410

VSR 420

VSR 430

Reverse rotation

✓

✓

✓

✓

Automatic door opening

✓

✓

✓

Automatic rotor clamp

✓

✓

✓

Second cutter for balancing 2 planes

✓

✓

✓

Automatic speed / cycle control

✓

✓

Oil mist removal

✓

✓

Automatic length set

✓

Integrated Cutter

✓

VSR 400 BENEFITS AND KEY FEATURES

Design

- Economically priced machine for the largest aftermarket and lowest volume OE manufacturer

- Versatile machine for all automotive and light commercial hubs

- Fastest Balancing Speed – Up to 300,000 rpm matching actual operating speeds

- Wide range of turbine housing adapters, standard and reverse rotation

- 3 stages of oil filtration with temperature control.

- Automatic oil drain

- Standard single-phase electrical connection

- Excellent air efficiency

- Robust steel cabinet

- Small footprint

- Touchscreen computer operation

Operation

- Intuitive operation:free training at UK headquarters

- User configurable software and templates

- Quick model change

- Automation options

- Two plane balance correction option

- Reverse rotation software included

- User interface language options

- VSR ™ vibration measurement in gpk

- Balance tests can be printed and saved

- Built in calibration

Warranty

- Remote technical support and software updates over the internet

- Used by Turbo Technics and major OEMs

- Fully tested and calibrated before delivery

- Safety interlocked, PAT tested, CE certified

- Manufacture in the UK

- 24-month warranty

The VSR 400 series is designed for great versatility and quick model change. The compact footprint, speed of operation, and simplicity of integration make it perfect for all workshops.

TECHNICAL SPECIFICATIONS

- Balancing speed: Ranges up to 300,000 rev / min.

- Impeller tip speed: Up to 550 m / s

- Maximum diameter of turbine wheel: approximately 85mm

- Maximum rotor length: approximately 180mm