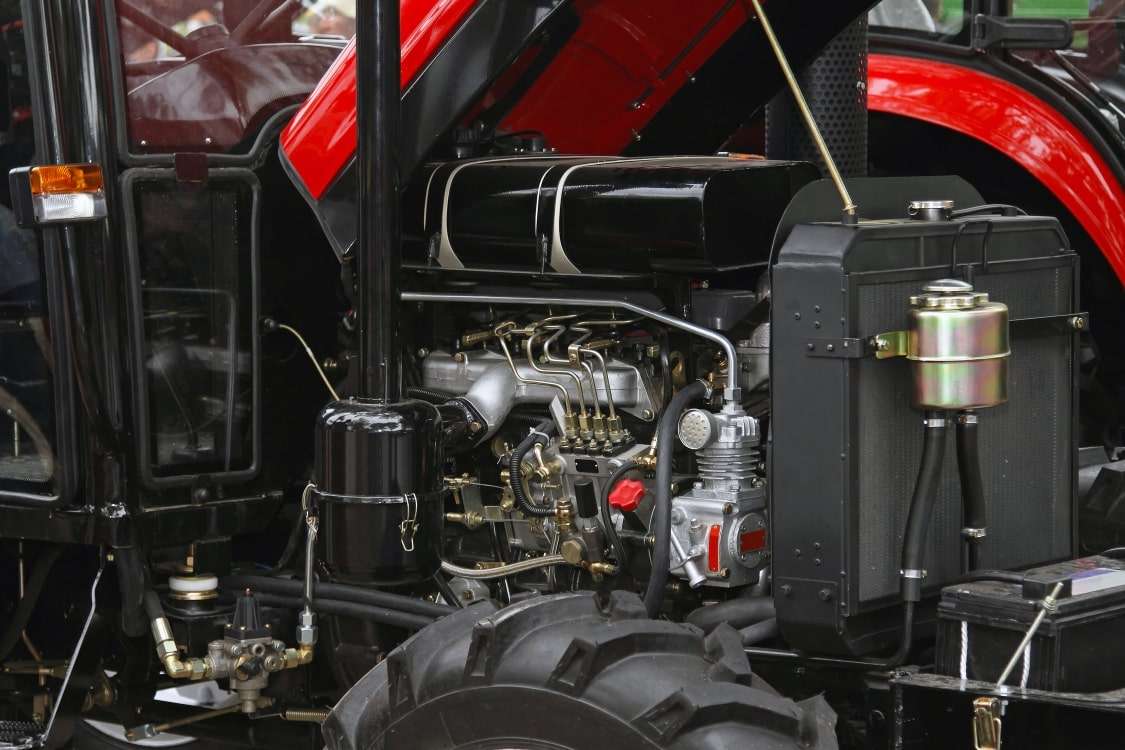

At Turbo3 we are specialists in turbos for engines of all types of tractors and agricultural machinery. Turbos for tractors with powers from 41 to 120hp, still very common today, with an average of 80 hp. and to which transport, lifting and various accessories are applied. Tractors with powers between 120 and 200hp. increasingly common. Tractors with powers greater than 200hp. suitable for large tracts of land and trawling capacity of all types of implements of extreme dimensions. We are official distributors of Garrett Turbos, Holset Turbos, Schwitzer Turbos, Continental Turbos, BorgWarner Turbos, Mitsubishi Turbos, IHI Turbos, PBS Turbos and Turbotechnics, in addition to supplying Komatsu Turbos and Toyota Turbos.

We are official distributors of BorgWarner Thermal Systems – Viscous and Electronic Clutch Fans – Visctronic. BorgWarner fans are factory installed on over 80% of tractors. We are also official distributors of Kendrion (formerly Linnig) electromagnetic clutch fans, miscellaneous applications, air conditioning compressor pulleys and related components.

THE 7 MOST FREQUENT FAULTS OF TURBOCHARGERS FOR TRACTORS

1. Impurities in the oil

Surely it is due to the solid particles in the oil (char, metal shavings, remains of solidified liquid joints, etc …

You have to check the oil, the oil filter, the oil pipes, the crankcase, check if the oil hoses are clogged, both the supply and return pipes.

Keep in mind that this breakdown can occur when the oil is contaminated, both because it has not been changed in time, or because it is deteriorated both because it is of poor quality and because it has worked in temperature conditions for which it was not designed. It also occurs when we have had a break in the engine and we have not removed the shavings or metallic remains of the broken parts from the crankcase. Also in some engines, the turbo lubrication hose passes very close to the exhaust manifold, so that the slightest movement of the hose makes this touch or is very close to the manifold, with which the oil becomes very hot at that point. , and it becomes carbonized, first slightly blocking the passage of the oil and finally coming to interrupt it completely.

2. Lack of lubrication

There may be several causes, lack of oil in the engine due to failure (crankcase breakage, lack of maintenance, etc …), breakage or obstruction of the hose that sends the oil to the turbo, improper placement of the gaskets, which obstruct the oil inlet, use of liquid seals that solidify obstruct the oil inlet (the use of these is prohibited, and also invalidates the warranty). Chemical contamination that is not visible also produces these faults (the most common is the mixture of water or fuel with the oil).

The first thing to check is that the level and state of viscosity of the oil is adequate, the inlet and oil hoses to the turbo, and the state and placement of the gaskets, and that the oil pump works and provides adequate pressure. Also that there is no breakage in the water pipes that communicate with the oil.

How to find out? The engine loses power and produces black smoke, the turbo can make quite a bit of noise and by rubbing the turbine on the exhaust it can turn red.

Keep in mind that, when the oil pump fails, lacks lubrication or decreases the oil viscosity, the first thing that fails is the turbo, which is the most delicate part of the engine, let’s not forget that the last passenger car turbos arrive at 200,000 rpm, which supposes the destruction of the turbo but is not very careful and well maintained.

3. Ingestion of a foreign object by admission

Surely the reason is at the entrance due to the admission of a large foreign object (metal washer, nut, etc.)

You have to check the air filter, the intake ducts, the hoses and clamps.

Keep in mind that, This breakdown generally occurs when changing the air filter, a tube or the turbo and forgetting or losing a washer or nut in the intake ducts. It can also be caused by some loose clamp on the sleeves and the aspiration of gravel or the like from the road.

4. Ingestion of a foreign object by exhaust 1

Surely it is due to a broken engine piston. You have to check the pistons and the exhaust manifold.

How to find out? Lack of power, engine failure and oil loss. The exhaust manifold and the exhaust shell are upholstered in cast aluminum.

Keep in mind that, at the same time that the engine and turbo are being repaired, the exhaust manifold must be cleaned or replaced so that no aluminum particles remain. Failure to remove the aluminum from the exhaust manifold by restarting the engine and warming up will melt and impact the exhaust turbine again.

5. Ingestion of a foreign object through the exhaust 2

This is most likely due to entry through the exhaust shell of a valve stem.

You have to check the valves and their seats.

How to find out? Lack of power and engine failure.

Keep in mind that, after repairing the turbo and the valves, check that no particles remain in the exhaust manifold or in any recess, and that it can be released when the engine is restarted and the turbo breaks again.

6. Ingestion of a foreign object through the exhaust 3

This is probably due to the entry through the exhaust shell of a foreign object (valve, piston piece, valve stem, exhaust manifold piece, etc …)

You have to check the valves, valve seats, pistons, exhaust manifold, etc …

Keep in mind that this breakdown occurs when a valve or piston breaks, also when particles are detached from the internal partitions of the manifold, or if the manifold has been welded without taking the precaution of removing the excess weld, which with the vibration of the engine falls off and hits the turbine.

7. Ingestion of dust, sand or salt by admission

Probably due to a broken filter, its absence, in poor condition, a loose clamp or a cracked sleeve, cause the entry of dust, sand or salt (scattered in winter to avoid ice).

You have to check the filter, the hoses, their clamps.

How to find out? The engine loses power and heats up.

Please note that you should strictly follow the manufacturer’s recommended reviews.

8. Valve does not act (standard pressure valve turbos)

The reason may be a rupture of the sleeve that carries the pressure to the valve

You should check that the sleeve does not touch any part of the motor (if this part is hot it deforms and breaks the hose) or that the clamps that hold the hose have not cut the hose.

How to find out? The engine has more power at high rpm since the valve does not cut off the turbo blow (Danger of engine breakage).

Keep in mind that this breakage occurs when handling the motor and not being careful, you can also forget to put the sleeve on after checking if the valve works.

Any questions you have please contact our Turbo specialists at Turbo3, we will be happy to help you.

We are specialists in turbos for:

CLAAS DEUTZ

FENDT JOHN DEERE

Mc CORMICK SAME

MASSEY FERGUSON

NEW HOLLAND

VALMET-CASE