VTR 100

THE MODEL

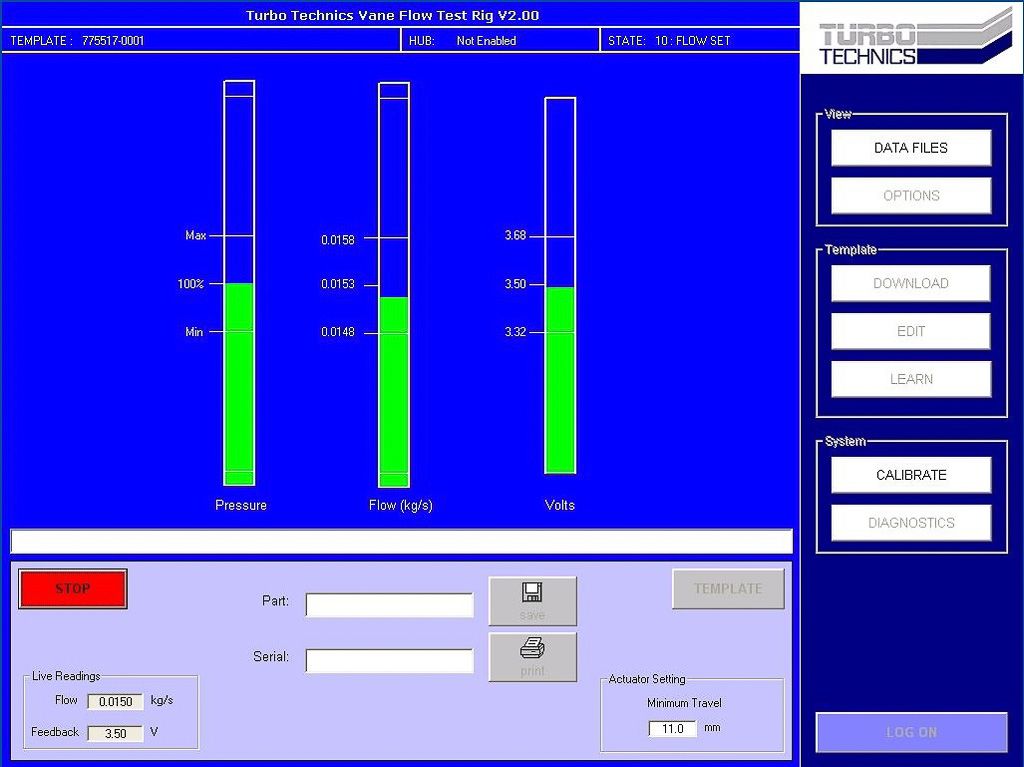

The Turbo Technics VTR (Vane Flow Test Rig) machines are built at TT UK headquarters to allow measurement and adjustment of air mass flow through variable geometry turbochargers. The machine has been designed to include automatic compensation for atmospheric pressure and temperature, providing consistent results in different environments.

The VTR100 is a simplified version of the VTR200, suitable for all light commercial passenger car and touring car applications, and is built to meet the needs of the smallest workshop. It is designed to configure VNT (Variable Nozzle Turbocharger) mechanisms to the required gas flow using TT-generated software templates. In addition to the wide range of templates supplied by TT, customer operators can create their own templates.

FLOW ADJUSTMENT PROCESS

ALL VNT TURBOS

This machine has the ability to control pneumatic actuators including vacuum, pressure, and vacuum with position sensors that provide voltage feedback. Turbos using electronic actuators can also be tested using an ATP 100 electronic actuator tester / programmer (available separately or built into the machine if purchased together)

Atmospheric pressure, altitude and temperature correction is built into the software. Flow adjustment on the VTR 100 is done with the turbo fully assembled, placing it at the base and connecting the air supply via inlet and outlet magnetic adapters to fit a range of different types of turbocharger flanges, including flange simple, V-band and collector.

Compressed air is supplied at a precisely controlled pressure and flow is measured. Altitude and temperature correction is applied and compared to the template. Then a ‘live’ adjustment is made to the turbo VNT mechanism until a pass is achieved.

Importantly, machine operation closely follows the methods used by OEMs on their production lines, providing a reliable setup procedure for the remanufacturing industry.

UK DESIGN AND CONSTRUCTION

LATEST TECHNOLOGY

As with all TT machines, the VTR 100 uses the latest touch screen technology, an intuitive interface, and built-in connectivity that enables remote TT technical support over the Internet. Easy-to-use software can be quickly mastered in a few hours with additional free training available at TT UK HQ if needed.

All Turbo Technics machines are designed and built in the UK and available through the TT dealer network.

VTR 100 BENEFITS AND KEY FEATURES

Design

- Economical machine for the smallest workshop.

- Suitable for testing cars and light commercial vehicles.

- Wide range of adapters and accessories.

- Quick model change

- Automatic correction of atmospheric pressure and temperature

- Standard single-phase electrical connection

- Excellent air efficiency

- Robust steel cabinet

- Integrated noise reduction.

- Small footprint

- Touchscreen computer operation

Operation

- Intuitive operation: free training at UK headquarters

- Extensive database of templates

- User interface language options

- Built in calibration

Warranty

- Remote technical support and software updates over the internet

- Fully tested and calibrated before delivery

- PAT tested, CE certified

- Manufacture in the UK

- 24-month warranty

The VTR 100 is designed for great versatility and a quick model change. The compact footprint, speed of operation, and simplicity of integration make it perfect for the small workshop.