VTR 200

THE MODEL

The Turbo Technics VTR 200 (Vane Flow Test Rig) was developed as part of a remanufacturing program for variable geometry turbos specifically targeting OEM vehicle manufacturers. The same technology is now available in the aftermarket for higher volume customers.

The VTR200 is designed to verify the flow and actuator characteristics of variable geometry turbos and to conform to the original manufacturer specifications.

Remanufacturers and repairers can now have the confidence to rebuild turbos equipped with variable geometry mechanisms knowing that they can reset those mechanisms to OEM equivalent configurations. Importantly, machine operation closely follows the methods used by OEMs on their production lines, providing a reliable setup procedure for the remanufacturing industry.

FLOW ADJUSTMENT PROCESS

ALL VNT TURBOS

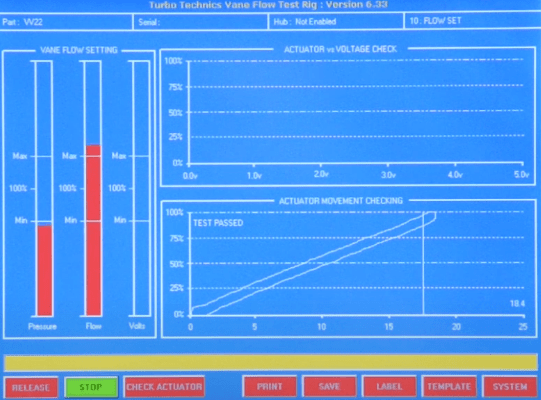

Unlike other flow verification machines available on the market, the VTR200 follows the same test method used by turbo OE manufacturers in original manufacture. The quick-release mounting adapter system allows the air connection to the turbo to be detached from the machine and then ‘plugged’ in for testing. The precision air measurement system ensures a high degree of precision, and the comprehensive software fully compensates for changes in air pressure, temperature, humidity and altitude, providing consistent results in all environments. Flow adjustments are made ‘live’, with the turbo fully assembled, speeding up the setup process, and the actuator response is graphically displayed on the screen. Position sensor voltages can also be displayed graphically, and test data can be saved / printed.

Mass flow is corrected to standard reference conditions and compared to a template supplied by TT based on original units. Then a ‘live’ adjustment is made to the turbo VNT mechanism until a pass is achieved. In addition to the wide range of templates supplied by TT, customer operators can create their own templates

The VTR200 can control both pressure and vacuum actuators as standard, with plug-in electronic actuator controllers available as add-ons for virtually all types of electronic actuators, including REA, SREA, CAN, and PWM. Compared to the VTR100, the VTR200 also tracks the movement of the actuator on the screen using an ultrasonic sensor, allowing adjustment and configuration of the bar length

UK DESIGN AND CONSTRUCTION

LATEST TECHNOLOGY

As with all TT machines, the VTR 200 uses the latest touch screen technology, an intuitive interface, and built-in connectivity that enables remote TT technical support over the Internet. Easy-to-use software can be quickly mastered in a few hours with additional free training available at TT UK HQ if needed.

A complete database of software templates can be accessed from TT via the Internet.

All Turbo Technics machines are designed and built in the UK and available through the TT dealer network.

VTR 200 BENEFITS AND KEY FEATURES

Design

- Economically priced machine for the largest aftermarket and lowest volume OE manufacturer

- Versatile machine for all turbocharged passenger cars

- Wide range of adapters and accessories.

- Quick model change

- Automatic correction of atmospheric pressure, temperature, humidity and altitude

- Standard single-phase electrical connection

- Robust steel cabinet

- Integrated noise reduction.

- Small footprint

Operation

- Intuitive operation: free training at UK headquarters

- Extensive database of templates

- Dedicated controller units control electronic actuators

- Quick release mounting system.

- Actuator rod length adjustment

- User interface language options

- Built in calibration

- Touchscreen computer operation

Warranty

- Remote technical support and software updates over the internet

- Fully tested and calibrated before delivery

- PAT tested, CE certified

- Manufacture in the UK

- 24-month warranty

The VTR 200 is designed for great versatility and a quick model change. The compact footprint, speed of operation, and simplicity of integration make it perfect for the higher-volume aftermarket and lower-volume OEM.