Garrett has a leadership record in Turbochargers for over 60 years in the world market. The Garrett Turbos range includes more than 3,500 models, from free flow and discharge valve turbos to revolutionary variable nozzle turbine technology and dual phase systems.

Garrett turbochargers are fully tuned to operate with the most advanced drive systems that integrate turbo control into the vehicle’s ECU.

There is a Garrett® turbo for almost any engine, for light diesel or gasoline vehicles: from 0.6-liter units to 12-liter engines, through all other references. We also have them for trucks and off-road equipment, the Garrett product range meets the needs of

engines with powers ranging from 60 to 4000 hp.

Almost all of the world’s leading car manufacturers have used Garrett technologies and innovations, resulting in approximately 100 million vehicles with our products and an average launch rate of 100 new applications spanning gas, diesel powered engines annually. , natural gas, electricity and fuel cells.

Garrett continues to pioneer turbo diesel technologies that help elevate the dynamics between fuel efficiency, emission reduction, and drivability in cars and light commercial vehicles. Our innovative boost systems open up engine sizing options for automakers through class-leading power density, while driving performance and helping to improve fuel economy and reduce NOx. and CO2 under real driving conditions.

Garrett’s broad portfolio of turbo technologies covers the widest range of applications for both gasoline and diesel engines.

Garrett Gasoline Turbochargers at Turbo3

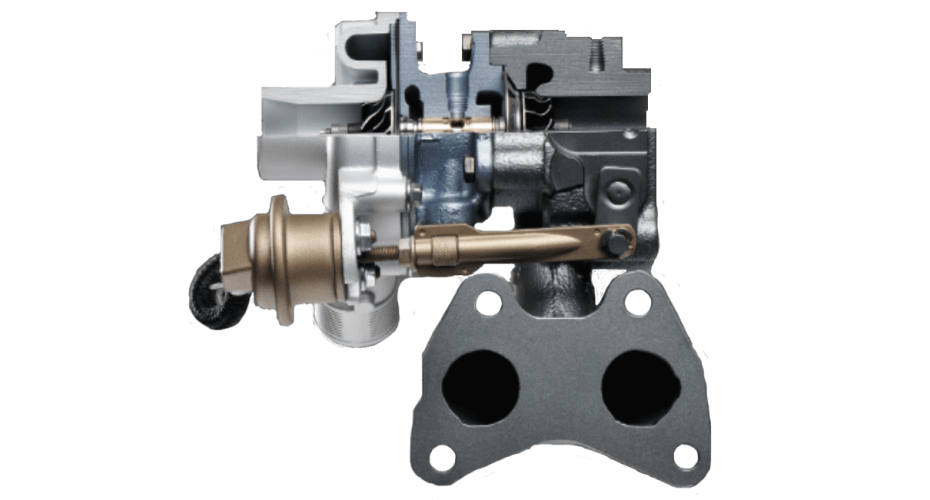

Achieving maximum performance is essential for gasoline engines in the midst of tightening fuel efficiency and emission standards. To enable smaller, lighter, and more efficient engines, Garrett’s Wastegate turbochargers For gasoline engines they use advanced aerodynamic systems, materials and bearings that maximize efficiency and power density at an optimized cost. Our Wastegate turbochargersfor gas engines are available in various single displacement and dual displacement configurations, ranging from span, <1L displacement to more powerful options up to 3L per turbo.

Wastegate Turbo Garrett Key Features

Garret’s Wastegate turbochargers have improved turbocharger performance through optimized aerodynamics. Our gasoline discharge turbos are equipped with wheeled turbines and compressors with radial, mixed, low and high flow capabilities. The new generation of wheels, as well as the compact volutes, satisfy the different requirements of low and high power motors.

Many modern gas engines use discharge turbochargers, which control boost levels through electrically operated bypass valves. Operating at higher temperatures than diesel turbos, they are often water-cooled and built using alloys suitable for the high-temperature aerospace industry.

Other key features include:

- Unique semi-floating bearing that is 30 percent smaller and reduces friction losses by 20 percent. Also available with ball bearing option.

- Redesigned recirculation valve that minimizes overvoltage.

- Electric actuator option for precise control and faster response.

Garrett Diesel turbochargers at Turbo3

From renowned Variable Geometry Turbo (VNT) architecture to innovative Two Stage designs, Garrett turbo systems take advantage of engineering advances in aerodynamics, materials, bearings and electric drive to set new benchmarks for performance and reliability.

Small Wastegate turbochargers for diesel engines

The small Gargate Wastegate turbochargers for diesel engines offer advanced performance, fuel efficiency and low emissions in a compact design. Our small residual discharge turbochargers for diesel engines are available for engines ranging from 0.8L to 3L, corresponding to powers ranging from 30kW to 120kW.

Wastegate turbos control engine boost levels by coordinating the actuator and bypass valves. At low speeds, the bypass valve closes to ensure maximum exhaust flow to the turbine and rapid turbo response on ignition. At high speeds, the bypass valve opens, limiting the exhaust gas entering the turbine and controlling the supply of blown air.

Other notable features include:

- Aerodynamic design focused on low-end efficiency.

- Z-Ultra bearings that improve low power torque and transient response

- Improved oil seal and blowing levels

- Optimized piston ring and seal designs

All of our small turbocharged turbochargers for diesel engines are designed to meet continuous sizing requirements.

Turbocompresores de geometría variable para motores diesel.

Garrett’s Variable Geometry VNT technology has been adapted to more than 70 million diesel engines in the past three decades. The advanced design of the turbo helps manufacturers to increase the engine performance of cars and light commercial vehicles, increasing fuel efficiency, reducing emissions, improving driving ability and improving packaging flexibility.

Two Stage Parallel Turbochargers for Diesel Engines

Garrett’s two-stage turbo diesel series combines the benefits of turbocharging by using two turbos in a series arrangement. This helps improve transient performance, offers better low-speed torque, and optimizes fuel efficiency in passenger and commercial vehicle applications. Automakers can use this technology to reduce engine size or increase performance.

Two-stage serial turbochargers for diesel engines

Garrett’s two-stage turbo diesel series combines the benefits of turbocharging by using two turbos in a series arrangement. This helps improve transient performance, offers better low-speed torque, and optimizes fuel efficiency in passenger and commercial vehicle applications. Automakers can use this technology to reduce engine size or increase performance.

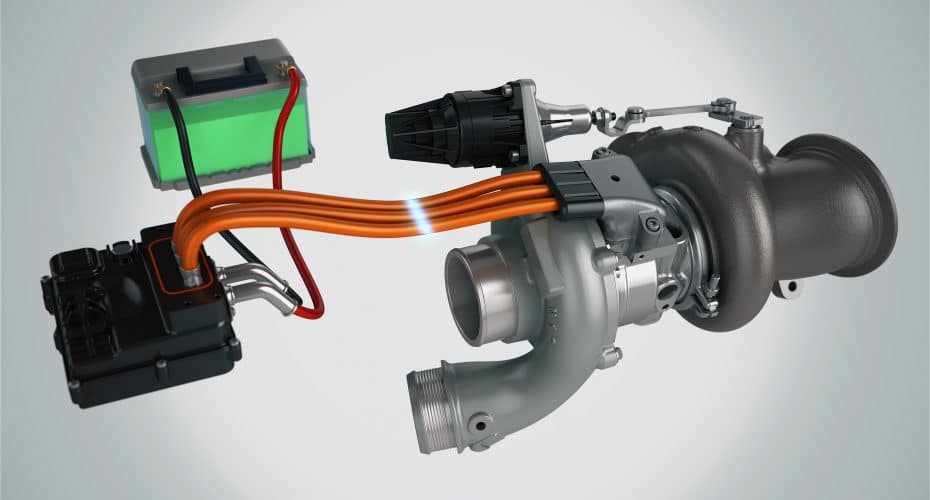

Garrett Motion introduced the electric turbocharger for the first time at IAA 2019

Growing trends towards hybridization open up possibilities for transferring electric drive technology from the racetrack to the road. Garrett is a pioneer in E-Turbo technology to deliver superior performance, fuel economy and emissions by integrating cutting-edge electric motors and power electronics into its turbocharger product families.

Electrified turbos (E-Turbos) show exciting potential and equal applicability in commercial and light vehicles, in all fuels such as gasoline, diesel, and natural gas (CNG).

Garrett turbos and competition

Garrett Motion is one of the world’s leading pioneers of turbo technology, providing engine drive systems to racers and enthusiasts around the world. You will find one of the largest ranges of turbochargers and intercoolers for racing and performance from 1.4L – 12.0L displacement with a power range of 140 – 3000. Standard and reverse rotation turbo options for symmetrical fittings and a full line of intercooler cores.

Garrett is a pioneer when it comes to the racing and performance industry. We are dedicated to designing and manufacturing the safest and highest performing turbochargers and accessories in the industry. For decades, we have provided momentum solutions that have helped race teams win races, championships, and world records. In the 1969 Indianapolis 500, a Lotus-Ford powered Garrett TE06 car crossed the finish line first.

Our engineers have continued to develop new products for racing enthusiasts that offer a wide range of drive solutions for almost any gasoline engine. 1.4L – 12.0L engines and 140 – 3000 horsepower. The Garrett GTX Gen II and G-Series product lines offer the latest advancements in turbocharger technology.

Our wide range of intercooler cores and Powermax vehicle-specific intercoolers provide superior thermal protection for today’s powered engines. Bar and plate technology combined with high-density offset fins helps reduce more heat than the original cores. This allows for a higher heat saturation point and less engine power reduction.

Turbochargers for commercial vehicles.

At Turbo3 we distribute and advise for the full range of Garrett commercial vehicles: Advancing Motion is the commercial vehicle partner of choice by driving custom technology solutions that deliver value to the end customer through superior reliability, performance and fuel efficiency.

DAVNT - Dual Axis VNT Turbochargers

Garrett offers the latest generation of Variable Geometry Turbo DAVNT (Dual-Axis VNT) offers robust, high-performance solutions that improve fuel efficiency, reduce emissions, and further enhance engine braking capabilities.

The Turbo DAVNT Variable Geometry Turbos (Dual Axis VNT), available in different sizes, are especially suitable for diesel engines with displacements from 2.5L to 15L, from small delivery trucks to large road trucks and off-road equipment.

Key Features of the DAVNT Turbocharger for Commercial Vehicles (Dual Axis VNT)

The Variable Geometry Turbo (VNT) mechanism in DAVNT, like its passenger vehicle counterparts, regulates the flow of exhaust gases in direct response to engine requirements through a row of mobile vanes located around the turbine wheel inlet. These turbine nozzle vanes are supported by two shafts for increased reliability and durability, in excess of 1.2 million life cycles. Garrett’s patented pressure balance channels exhaust gas to both sides of the blades, thus avoiding heavy axial loading and reducing friction and wear while improving controllability at the same time.

The advantages of dual-axis VNT turbochargers for commercial vehicles are that the DAVNT VNT turbochargers allow independent control of the air-fuel ratio and EGR rates, helping commercial vehicle manufacturers meet the NOx emissions targets and particles without compromising fuel efficiency and performance.

Furthermore, it has higher motorcycle power and torque output compared to fixed geometry turbochargers, with a reduction in engine back pressure, resulting in better engine performance, better driving ability and lower fuel consumption. fuel.