Mitsubishi Turbo is one of the most powerful quality turbocharger manufacturing groups used in almost all car manufacturers: VW, Audi, Daimler, Toyota, Ferrari …

Mitsubishi Turbocharger and Engine Europe BV: excellence in transforming energy into motion

Mitsubishi Turbocharger and Engine Europe BV is a global leader, mainly in the fields of:

– Turbochargers for the European automotive industry

– Diesel and gas engines for marine applications, industry, construction and agriculture.

Its turbochargers and engines are top quality. Therefore, the strong growth of the company is not a coincidence. All major European car manufacturers equip their engines with Mitsubishi turbochargers and their engines meet the requirements of the world’s leading classification societies.

Central location

Mitsubishi Turbocharger and Engine Europe BV is a group company of Mitsubishi Heavy Industries Ltd. Japan But it has been trusting for years in its official distributor in Spain in Turbo3. The Mitsubishi company is subdivided into two divisions: turbochargers and engines. The head office, production and assembly lines are located in Almere, from where the ports of Rotterdam and Amsterdam are easily accessible.

Focus on clients

Not only direct customers play a central role, but their respective users are also important to both divisions. They are a professional and reliable partner. All for the benefit of the end user and to get a Turbocharger of the best quality and performance.

Superior quality

Believing in superior quality is the key, constantly innovating. This is also one of the main criteria when selecting suppliers and distributors worldwide. Mitsubishi Turbocharger and Engine Europe BV has an extensive and complete quality management system that is used throughout the company. All quality certificates relevant to the sector are present.

Environment

The environment is of great importance. They continuously optimize energy consumption and a great effort is made to minimize the production of harmful waste. To protect the environment as much as possible, they achieved ISO 14001 certification for their environmental management system. The certificate guarantees that they are committed to protecting the environment.

Optimal working conditions for the development of the best product

For Mitsubishi Turbocharger and Engine Europe BV, good and safe working conditions are important issues. But they go even further, having an extensive occupational health and safety management system on behalf of employees. They invest in their employees by providing training opportunities.

Ready for the future

Mitsubishi Turbocharger and Engine Europe BV is a progressive organization and operates in accordance with the principles of the Japanese philosophy Kaizen, 5S, Lean Manufacturing, Six Sigma and Total Productive Maintenance (TPM), with a focus on continuous improvement. In this way they maintain their superior position and are ready for future challenges.

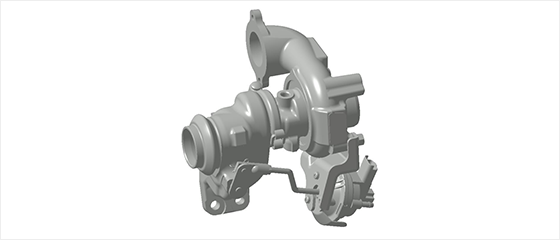

Turbochargers

At MTEE, they range from R&D to production and sales to all of Europe’s leading automakers. With an annual production of more than 3 million turbochargers, they are experts in this field.

Mitsubishi turbocharger and the Europe BV engine started turbocharger production in 1991 and have recently produced thirty million turbochargers. They are a MHI group company that already started production of turbochargers in 1957 and applied this experience to establish our company to manage the European market. Today, its turbocharger division in the Netherlands ranges from R&D to production and sales to major European car manufacturers.

With an annual production of more than 3 million turbochargers, they are experts in this field. In addition to that, its sister companies MTEA (USA), MTA (Thailand) and SMTC (China), support the demand for turbochargers in the other regions of the world and ensure that MHI remains a strong player in the global industry of turbochargers. With the continued strengthening of emissions legislation, the global demand for turbochargers will grow enormously in the coming years. With an annual production capacity of more than 10 million turbochargers and growing, MHI is well prepared for this growth in demand.

From the beginning, they have implemented state-of-the-art production equipment for their production and assembly operations, and this policy has been followed ever since. Its production lines are highly automated and operated by well-trained and accurate production personnel. In their production process, they have several stages during which the pieces are verified in different ways according to their strict quality procedures. Parts are automatically rejected if they don’t meet specifications, and their assembly lines are equipped with smart solutions that prevent assembly from continuing if parts are incorrectly assembled.

Turbochargers for gasoline vehicles

While previously applied primarily to diesel engines, the turbocharged gasoline engine market started to take off about 10 years ago. As emissions regulations tightened, the application of turbochargers provided a perfect solution to downsize by reducing fuel consumption without penalizing engine performance and driving ability.

The turbocharging concept is fundamentally the same for gasoline and diesel engines. However, there are some differences due to the different combustion processes of fuels.

In a gasoline engine, the air / fuel ratio required for ignition is very sensitive and must be precisely controlled. In a diesel engine, the air / fuel ratio is always “lean” due to excess air. Therefore, exhaust gas temperatures are generally higher in a gasoline engine than in a diesel engine (~ 950-1050 ° C). Therefore, the turbocharger for a gasoline engine requires advanced materials to withstand the high thermal load conditions. Special alloys, including expensive materials like nickel, are commonly used for these turbochargers.

Heat transfer from the hot turbine area to the bearing housing is protected from these high temperatures by the application of a full water jacket and an optimized internal heat shield. This prevents heat damage to the bearing housing as well as other components.

As European emissions laws are pushing new limits, many future gasoline applications will depend on Variable Geometry (VG) solutions.

A VG system allows the turbine operating point to be adjusted continuously during all engine operating points, significantly improving fuel efficiency. In addition, MHI has developed technologies for gasoline vehicles, such as dual-displacement anddual-input turbines, that provide a significant reduction in turbo lag.

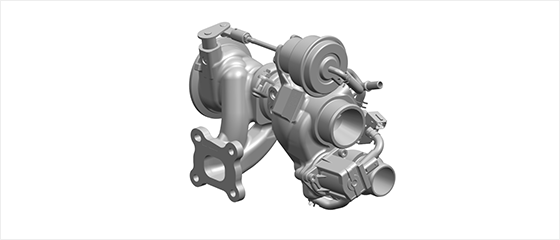

Turbochargers for diesel vehicles

Turbochargers have traditionally been applied primarily to diesel vehicles, and almost all diesel vehicles in Europe are turbocharged today.

The turbocharging concept is fundamentally the same for gasoline and diesel engines. However, there are some differences due to the different combustion processes of fuels.

In a diesel engine, as the piston approaches TDC (top dead center) during the compression stroke, fuel is injected and combustion occurs spontaneously due to high pressure and high temperature in the combustion chamber. For diesel applications, the compression ratio of the engine must be high to start combustion.

This leads to a higher maximum pressure, while the exhaust gas temperatures are generally lower than in a gasoline engine (around 800 ~ 850 ° C) due to a combination of higher engine and process expansion ratio lean burn. Therefore, the material composition of the turbocharger is generally different from that of gasoline applications.

Currently, the diesel vehicle market is declining. Due to the combustion process, NOx formation is greater than in a gasoline engine and specific after-treatment systems (NOx traps, SCR, etc.) are required to comply with regulations. It will be difficult for diesel vehicles to be profitable and therefore smaller class diesel vehicles are expected to completely fall out of the market in the near future.